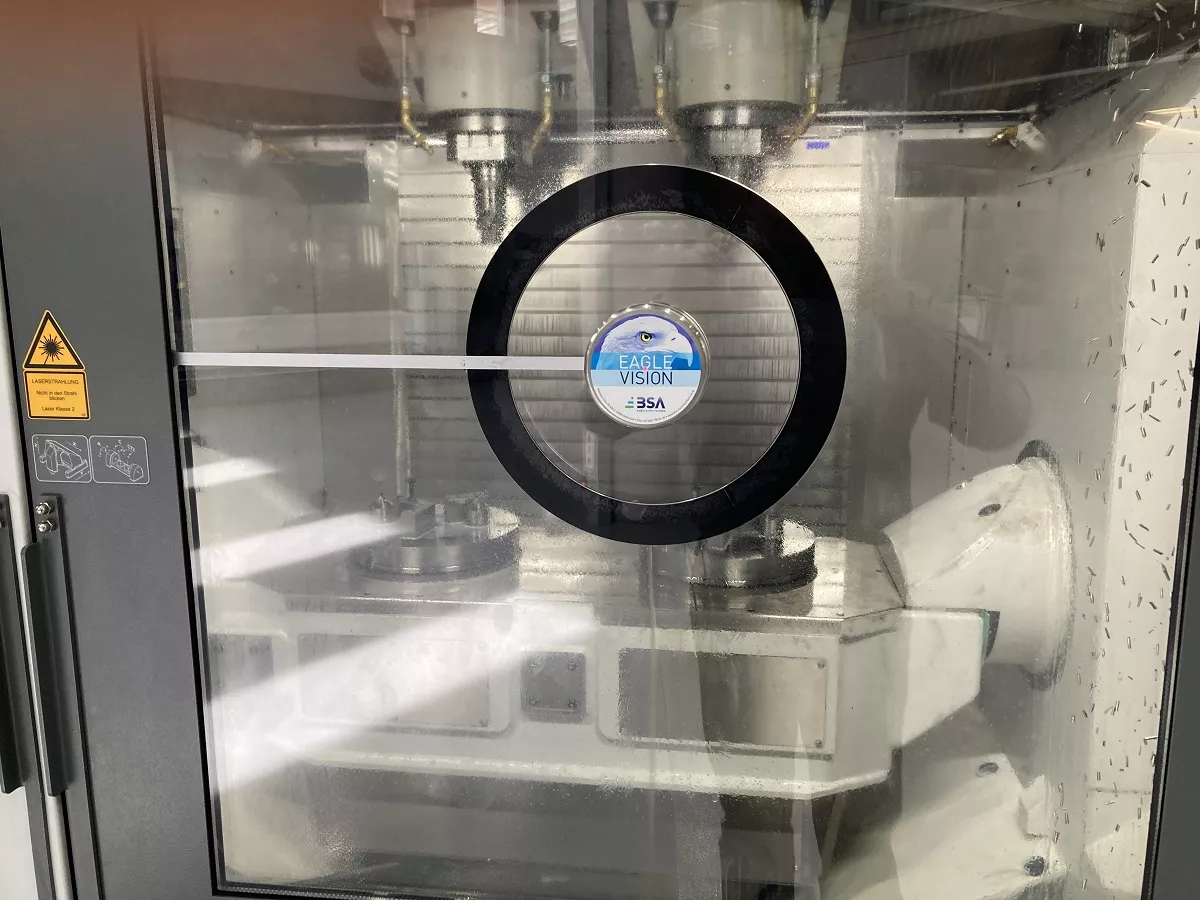

Chiron DZ 22 S mill turn

CNC turn-/mill center (DEMO MACHINE)

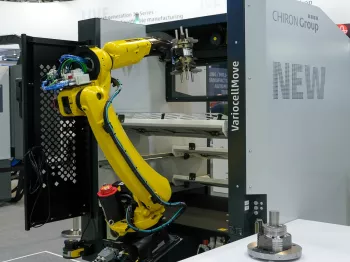

Introducing the CHIRON DZ 22 S Mill Turn – the epitome of versatility and productivity in machining. This state-of-the-art machine combines milling and turning operations into a single powerhouse, boasting dual spindles for unparalleled efficiency.

The CHIRON DZ 22 S is engineered to tackle the complete machining of large-volume components such as electric motor and gearbox housings, oil pans, as well as various automotive suspension parts. Its adaptability to diverse manufacturing needs makes it an indispensable asset in any modern production environment.

Crafted in a gantry design, the CHIRON DZ 22 S ensures exceptional stability and precision while delivering supreme dynamism. Its robust structure guarantees reliability even under the most demanding machining tasks, empowering manufacturers with the confidence to achieve superior results consistently.

One of its standout features is the lightning-fast tool changer, renowned as one of the swiftest in its class. This rapid tool change capability minimizes downtime, optimizing productivity and maximizing throughput. With a spindle distance of 600 mm, the CHIRON DZ 22 S offers the flexibility to efficiently and precisely machine a wide range of components.

Overall, the CHIRON DZ 22 S Mill Turn represents the pinnacle of machining excellence, setting new standards in precision, efficiency, and versatility. Its innovative design and top-tier performance make it a game-changer in machining technology, elevating productivity and enhancing competitiveness for manufacturers worldwide.